Ls-F7 Automatic Setting Wrapping Box Making Machine

Overview Automatic Setting wrapping box making machine(LS-F7) Product Description Remark 1.Max and min case size depends

Description

Basic Info

| Model NO. | LS-F7 |

| Warranty | 1 Year |

| Certification | ISO9001, ISO, CE |

| Application | Commodity, Machinery & Hardware, Textile, Alcohol, Toy, Chemical, Apparel, Gifts & Arts, Dining, Medical, Food |

| Driven Type | Electric |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Type | Rigid Box Making Machine |

| Automatic Grade | Semi-Automatic |

| Voltage | 3.2kw/220V |

| Weight | 1150kg |

| Dimension(L*W*H) | 1200*1120*3100mm |

| Working Speed | <20PCS/Min |

| Function | Box Wrapping |

| Application-1 | Rigid Boxes, Gift Box, Cases, Paper Packaging |

| Application-2 | Boxes for Shoes, Phone, Shirts, Jewelry, Gifts |

| Transport Package | with Paper, Film and by Wooden Pallet. |

| Specification | Machine dimension: L1200*W1120*H3100mm |

| Trademark | LXS |

| Origin | Dongguan, China |

| HS Code | 84413090 |

| Production Capacity | 30 Set/Sets Per Month |

Product Description

Automatic Setting wrapping box making machine(LS-F7)Product Description

| Type | LS-F7 |

| Max box size | L430*W350*H110mm |

| Min box size | L80*W65mm*H10mm |

| Motor power | 3.2kw/220v |

| Air supply | 10L/min 0.6MPa |

| Working speed | <20pcs/min |

| Weight of machine | 1150kg |

| Machine dimension | L1200*W1120*H3100mm |

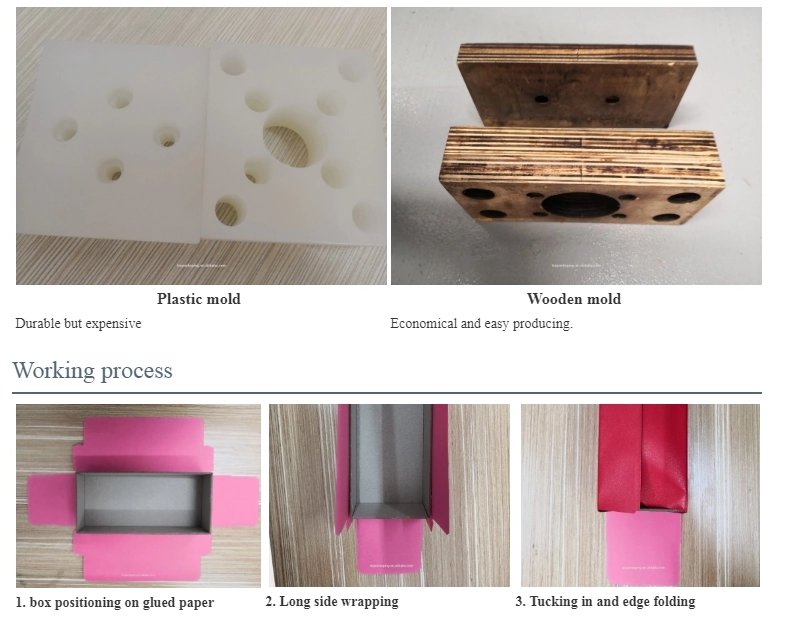

1.Max and min case size depends on the size and quality of paper2.The working speed decided by materials, glue, and the skill of the operator3.Compressor is not included in this machine

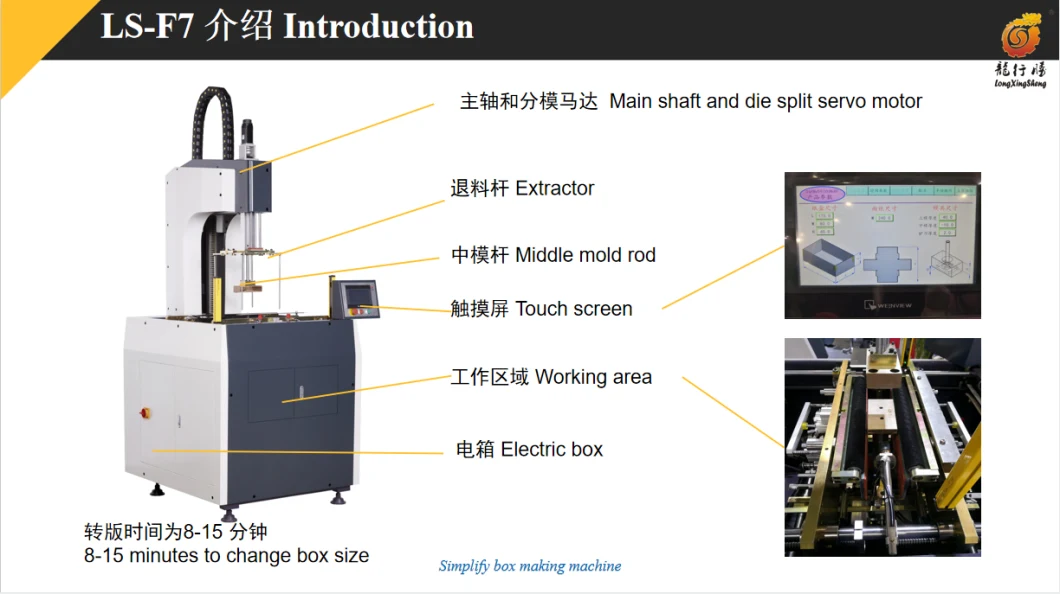

About LS-F7

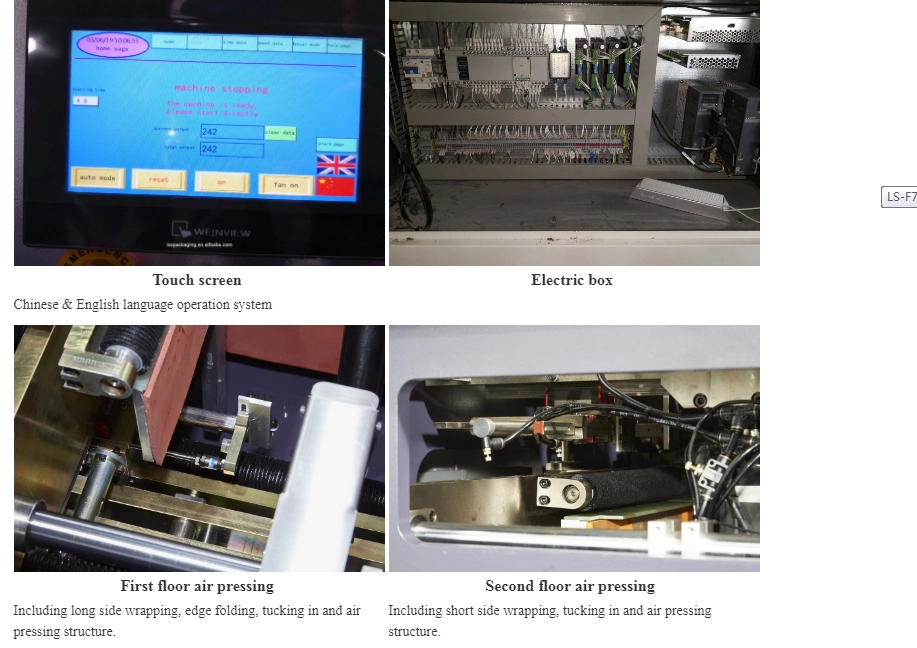

LS-F7 Smart rigid box making machine is applied for wrapping the cover paper on the pasted box. When we get a new box, installed the box mold on machine, input its data on the LS-F7 touch screen. Including the box length, width, height, cover paper width, top mold height, middle mold height and tucking in blade thickness. Then press caluate, machine will automaitc come to home position and move to setting position. Load a box to checking the setting and ensure each setting is fine. Then machine can start working. Whole process will cost 8 minutes. This machine will finished the side wrapping, edge folding (edge folding length ≤100mm), tucking in and air pressing at one time. No need to change air pressing board, tucking in blade. Air pressing structure has been divide into two floor, so that whole machine will cost around 3 s for finished one box. It is an ideal equipment for changable small orders.

Our Advantages

Certificates: ISO9001-2008, Quality management system, CE certificate.Mission & Vision: Provide smart modular for packaging. Products scope: Automatic rigid box making machine. V grooving machine. Visual positioning machine. Rigid box former. Corner pasting machine. Gluing machine and other machinery.Market positioning: Middle and high-end marketSpace of Dongguan Fty:10598m2Major market: America, Europe, Asia, Mid-east.

FAQ

Q: How could I pay?A1: We prefer T/T or L/C at sight. If you prefer other payment terms, please contact us freely.Q2: What is your packing way? Can I have the customized package?A2: We have the standard export package. For more details about the customized package, please contact us.

Q3: What is the delivery lead time?A3: It depends on the order quantities. The mass production lead time is about 7-12 days after receipt of the deposit.Q4: Are you a factory or a trading company?A4: We are a factory. We provide all kinds of OEM/ODM services for clients around the world.Q5: Where is your main market?A5: We export to the North America, Southeast Asia, Europe, Korea, Japan, and other countries.

Prev: St9000 Staple Tagging Machine Accessories 13mm Blacktup Staple Pin

Next: Cylinder Spare Parts for Sock Machines with Good Price

Our Contact

Send now