UV Light Irradiation Cross-Linking Cable Manufacturing and Processing Machinery

Description

Basic Info

| Warranty | 1 Year |

| Transmission Type | Flexible |

| Automatic Production Line | Assembly |

| Certification | CE |

| Automation | Automation |

| Flexible Production | Intelligent Manufacturing |

| Rhythm | Flow Production Line |

| Production Scope | Parts Production Line |

| After-sales Service | a Lifetime |

| Total Power | 22kw |

| Control System | Delta or Siemens |

| Apply Color | Red/Yellow/Green/Blue |

| Cable Material | Add Special Optical Initiators |

| Irradiation Form | UV Lamp |

| Transport Package | Plywood |

| Trademark | Hapro |

| Origin | China |

| HS Code | 84794000 |

| Production Capacity | 100/Year |

Product Description

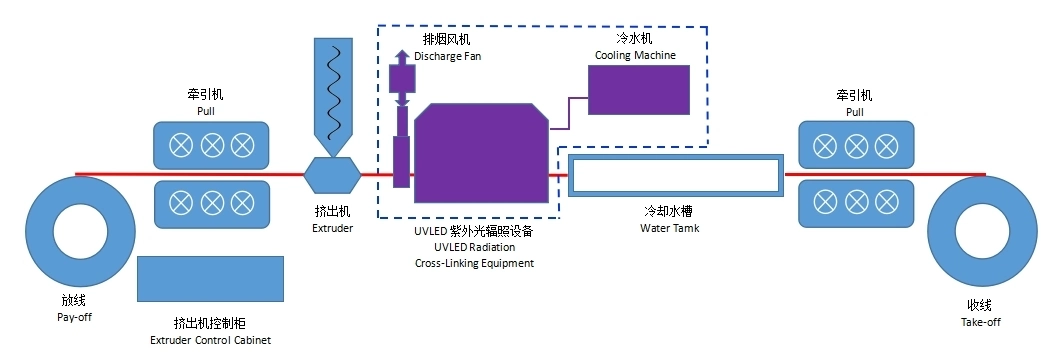

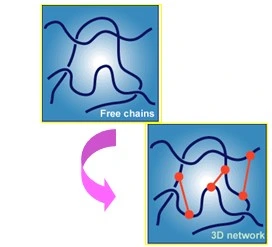

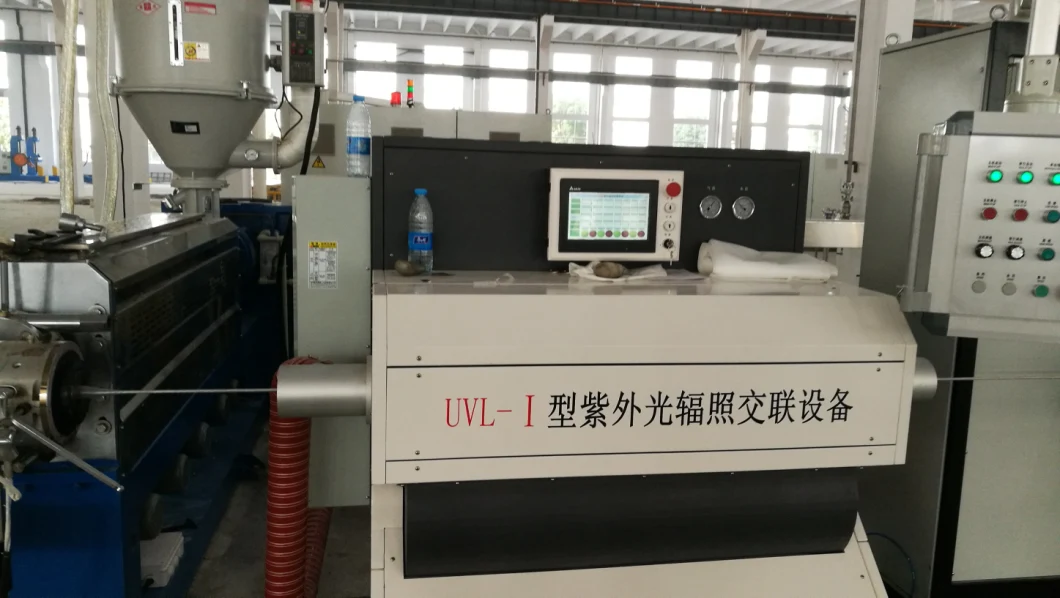

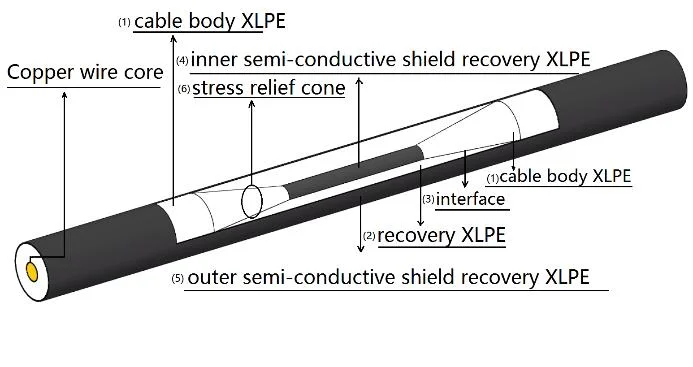

The LED light sources were mounted in a tunnel structure. The light radiated the center of the tunnel where the manufactured wire and cable go through. The radiation power can be set from 0 to 100% smoothly.Optical lens adopts imported ultraviolet fused quartz and vacuum coating technology, which greatly improves the utilization rate of ultraviolet energy. The advantages of UV-LED system over traditional UV lamp system and electron beam radiation and crosslinking:

vLow energy consumption :UV-LED system is only consume 1/4 energy comparing that of traditional UV lamp system at same production,1/30 energy comparing that of electron accelerator.

vFast production:Compare to crosslinking, and consigned electron beam processing, the crosslinking processing is finished simultaneously with the extrusion.

Low production cost:No intermediate movement and storage of the product, save the human power and additional cost. Low cost of UV radiation compound.

vLong life expectancy of the system :Life expectancy of the LED device is 4000 hours,no bead loss in normal working environment, and the perfect output power stability, See the life comparison table.

Environment friendly:The wave length is only 5nm band width, no short wave length UV energy induced Oz emission, no infrared and heat radiation, no strong visible light pollution. Ozone discharge is included into Emission standards for odor pollutants,US stipulate 0.1ppm, China stipulate 0.15ppm,UVL-I equipment won't products ozone.A water cooling system and a 2kW air blower are needed for extracting small molecule emission from the material during extrusion to keep the tunnel clean.

vSmall in size, easy to installation: The system can be inserted in traditional plastic insulating extruding production line, 1.8-2.0m in length and 2.5-3.0m in width in between extruding die and water trouph, water cooling system can be arranged properly.

Easy to operation :Pneumatic turn open and close the tunnel structure, make the conveying of the wire and clean the lens easy and ordinary operator can do it.

Low cost of maintenance:No lamp should be change, and no reflector should be replaced. The daily maintenance is only the clean of the lens surface by soft paper. For electronic beam system, maintenance is a heavy task.

| crosslinking | Electron accelerator irradiated crosslinking | UVLED irradiation crosslinking | |||||||

| Equipment investment | Low(steam room or warm pool) | High | Medium | ||||||

| Energy consumption | High(Long heating) | High(>600kW) | Low(<22kW) | ||||||

| Production cost | High | High | Low | ||||||

| Production cycle | Long (Secondary processing) | Long (Secondary processing) | Short (Online crosslinking) | ||||||

| Heat shrinkable | large | large | small<2% | ||||||

| Medium pressure lamp | Electrodeless lamp | UVLED irradiation crosslinking | |||||||

| Equipment investment | Low | High | Medium | ||||||

| Energy consumption | 70 kW | 80kW | 22kW | ||||||

| Maintenance cost | High | High | Low | ||||||

| Production speed | Low | Low | Fast (Online crosslingking) | ||||||

| Lamp life | 500 hours | 8000 hours | 40000 hours | ||||||

| Consumables | Lamp tube, reflector plate | Lamp tube, reflector plate,magnetron | No | ||||||

| Stability of production speed | Bad | Bad | Good | ||||||

| Environmental | Ozone | Ozone | No Ozone | ||||||

| Operation | Complex | Complex | Simple | ||||||

| Floor space | Large | Large | Small | ||||||

- Technical parameters:

| Item | Name | Specification | |||

| 1 | Power supply | 3 phase 380V+N+PE ,50Hz | |||

| 2 | Power consumption | Total power consumption : 22kW ; Radiation box : 14kW ; Chiller : 5kW ; exhaust fan: 3kW | |||

| 3 | Irradiation diameter | 0~30mm | |||

| 4 | Dimensions | Radiation box :1500*1300*1615mm(L x W x H)/ Chiller:1500*800*1800mm(L x W x H) | |||

| 5 | Light source | The self-developed UV LED light source adopts the proprietary chip from the world's top manufacturers.It has high energy output and the unique design of the optical system by using hybrid wavelength technology, adopts imported special material of glass processing into special lens. It has lower energy loss by coating the lens surface , It adopts the liquid cooling system to get longer LED life. | |||

| 6 | LED CPS | The self-developed power module adopts the Japanese imported chip and adopts the vacuum irrigation technology to protect it.It has overload, short circuit, circuit breaker, over-current, over-voltage and over-temperature protection.Multi - channel redundant distribution,network control. | |||

| 7 | Power output | Output optical power 0~ 100% (Real limit to 20%~100%) | |||

| 8 | Lamp life | Under normal rated power usage, the life of the LED lamp has decreased to about 70%, which is over 30000 ~40000 hours. | |||

| 9 | Production speed | Please refer to the actual production speed table | |||

| 10 | Characteristic | Low energy consumption,Online cross-linking ,Low production cost,Long life,One key to start & Easy operation,Low maintenance costs, Environment friendly, No Ozone | |||

| 11 | Cooling way | Liquid cooling | |||

| 12 | Safe guarding | Current monitor, Temperature monitor, Scram button,Extinction alarm, Chiller alarm; Constant temperature control from air conditioner | |||

| 13 | Exhaust smoke | Smoke purifier or High pressure exhaust fan | |||

Our Contact